|

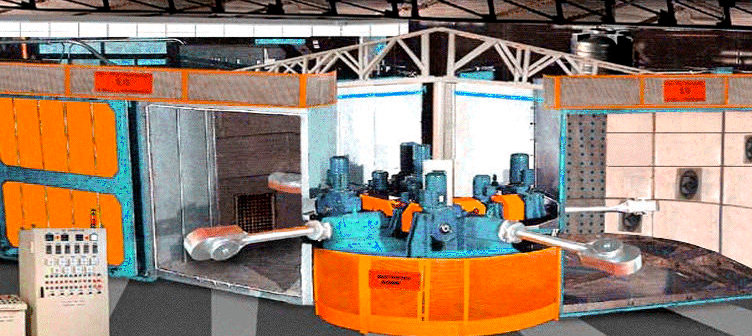

Independent Arm Rotational Moulding Machinery Independent Arm Rotational Moulding Machinery

|

|

|

|

Independent Arm Machine is widely used in rotational molding industry. These machines has each arm on a separate cart, which provides a multiple-station arrangement for cooling, heating and servicing. The cart indexes a center pivot post and has a joint load bearing track. The floor plan of this machine provides five process stations:

- Cooling

- Load

- Oven

- Pre-cool or Intermediate

- Unload

These machines can be availed with only single cart or arm. Importantly, three more arms can be added in the machine without modifying the technical configuration of the machine. Double cooling stations or double ovens are also available at the first place and can be added as per the modular technical drawings of the independent arm concept. Custom designs are also available for buyers to choose their preferred range.

Working Cycle:

This machine is available with six stations for utmost flexibility, which includes the following:

- Molding and Cooking the article

- Mold cooling station

- Material loading

- Intermediate phase for cooling

- Pre-Molding station for second layer

As per customer requirement, the work station is subjected to variation in a preferred manner. The various important features of Independent Arm Machines are as follows:

- In order to handle the machine swiftly, there is high tech control facility

- In the head of the arm of the machine, special bevel gears are installed

- Use-friendly interface for smooth operation

- There is an air flow design of the cooking chamber

- The arms have large loading capacity

- Innovation systems for closing and opening the oven doors.

- The thermal insulation of the cooking chamber is highly effective

- For less fuel consumption, electronically controlled burner is fitted out.

- In the closed circuit, heating is done with high velocity.

- The oven is outfitted with sliding gates and doors.

- In order to heat the molds, the oven measures and adjust the temperature in real time of the system.

|

|

|

|

|

|